How to transition your industrial process to A.I.

Every single day, we hear a new Artificial Intelligence success story : winning video games competition, health diagnostic or allowing Mona Lisa to talk. A.I. is for sure the future, but how can you transform this impressive showcases demos to real-world productivity improvement?

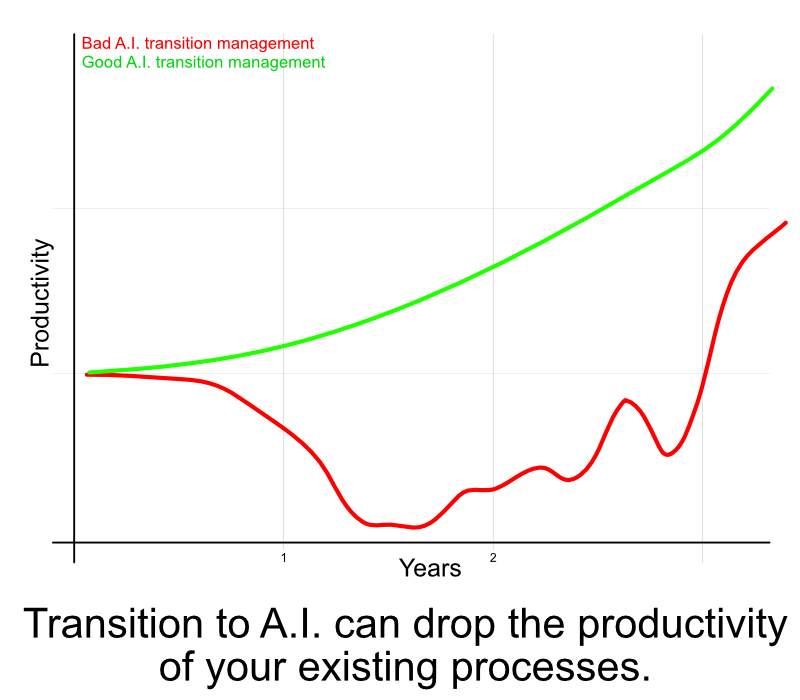

We always hear the same question: How to transition to A.I. without killing productivity for years.

Over the years at Cornis, we’ve helped wind industry leaders to transition seamlessly from a mostly human process to an automatized one, here are the steps we follow.

1. You have one job

Start by deciding which job, which tasks you want to automatize and concentrate your transition on it.

We’ve seen many companies trying to apply A.I. everywhere at the same time and that are still waiting to see productivity improvement today.

To define an effective scope, we ask these questions:

What is the input data?

The company we work with always have a vague idea of what is their input data: Inspection pictures.

The more you can describe your input data, the smoothest the transition will be.

Input data are every elements your teams need to do the job: images, on-site written information, cultural or expert knowledge, etc.

In the case of inspection pictures, do you have a procedure describing how you acquire these data? Do you have a specific camera designed for the job? Is there more data available? Does your technician fill out a paper describing the mission? Do you get the pictures in folders, ordered or mixed with non relevant content?

If you use your process thousand if not millions of times each year, your input data must respect guidelines. Take these guidelines and examples of data to figure the similarities on this task input datas.

Who is doing the job?

The people doing the job you try to automatize thanks to A.I. are the ones who know the best how to do the task and what to expect from an automated process.

A major part of the A.I. transition is to transfer people’s experience to artificial intelligence algorithms. It’s essential to find every person that contribute to the task you want to automatize.

What is the expected result?

The usual answer to this question is a report or an Excel file. If you have an online process, be more specific to make the transition easier; you don’t want to spend most of the time of your A.I. project automating report generation.

In the case of wind turbine inspection, we focused on determining if a picture has a defect or not, leaving the other part of the process out of scope.

The more you describe your expected result the easiest it will be to train and improve machine learning algorithms.

2. Explain like I’m 5

Headlines presenting machines as smarter than humans are only marketing.

Machines are dumb, but they have huge memory and computing power. Humans are smart, but they have low memory and computing power.

You need to split the task into simple steps to allow the machine to learn it.

This is one of the most laborious tasks in order to integrate Machine Learning in your business since it asks to deliver your expertise in such a way that anyone can understand it, particularly the developers that will have to automatize the task.

When we automated expertise on wind turbines, we identified a simple sub-task that represented 90% of the job and needed very low expertise : defect identification. We decided to automatize this first task which - half a year later - led to dividing by two the expertise time.

3. Design your workflow with no automation

To manage an A.I. transition, your process needs to be robust enough so it still works in case of no automation.

Before being an automated process, the automation will be partial : Machine Learning algorithms will only be efficient on a small percentage of your input images.

In the early stages, A.I. algorithms quality differs significantly from one input to another . Be ready for the worst-case scenario if you don’t want a productivity drop.

When we developed panoblade production chain, we had around 10% of automatic repositioning to stitch the images. It went from 90% of the images stitched for few inspections to 0% for most of them. We delivered every inspection on time thanks to an architecture designed for failure, whatever our algorithm performance.

Your A.I. enabled workflow needs to work well without automation.

Don’t replace your good old manual process, transform it to be A.I. Ready by ensuring these two elements:

You need a quality assessment procedure.

Describe how you assess the quality of your work : what are the steps? Can you give a quality score?

An automated quality assessment procedure is not mandatory, you can still achieve very high quality assessment productivity thanks to well designed User Interfaces.

You need to have a tool to correct a proposition. You have interfaces to do the task you automatize, you need to make sure these tools are ready to correct an A.I. proposition.

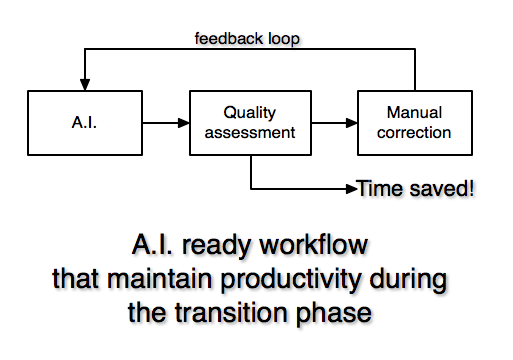

As soon as you have these two elements, you can start using A.I. in your process:

- You process every new data through your early stage A.I. algorithm

- The quality assessment procedure helps you select the data to correct

- Using the correcting tool, your users can adjust the A.I. response

- A feedback loop allows the A.I. algorithms to improve results

In our experience, most of the time, you start saving time right from the beginning because assessing the quality of a task takes usually less time than doing the job.

This architecture allows you to have constant feedback on the Machine Learning processes.

You will use Quality Assessment results to track your A.I. performance and to retrain your algorithm on the errors.