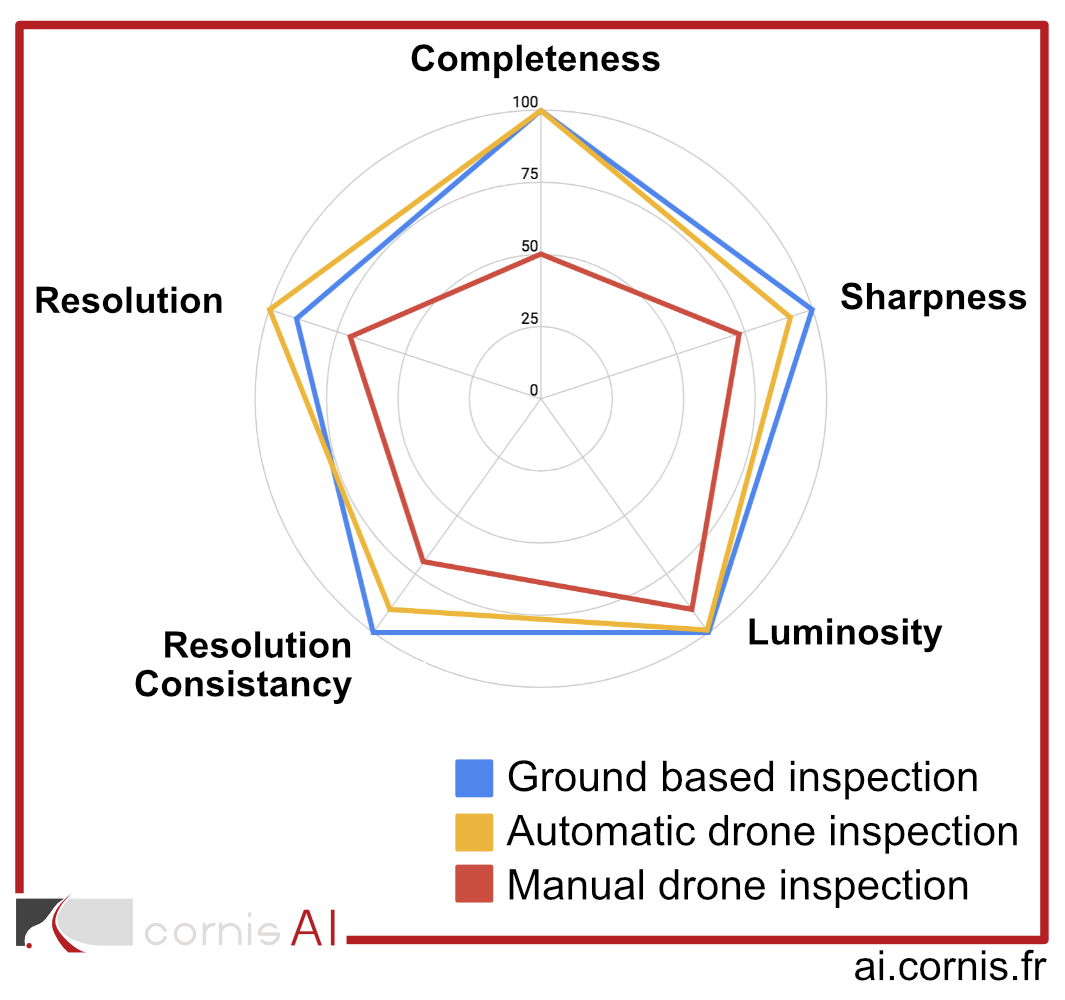

The 5 main metrics to assess image data quality

When doing inspections, the worst case scenario is to have to redo an inspection because the data acquired is not good enough to do an assessment. To check the quality of the data we process, we have built five metrics to have an objective and measurable point of view on the quality of the data and onsite acquisition work.

Completeness

If you want to be able to perform a complete expertise of a blade, you need to be sure that 100% of the blade surface is recorded. At Cornis we recommend to have 4 sides of each blade and at least 50% of overlap between images. This allows you to have high quality images and with the overlap, if one acquired image has a problem, the two surrounding images can replace it. You can lower this constraint if you use automatic image quality check tools.

Sharpness

Even if the acquisition system you use is taking high resolution pictures, blurry pictures can prevent experts from correctly viewing and assesing the blades. The Sharpness of an image is something that can’t be corrected afterwise so it needs to be assessed and controled on site.

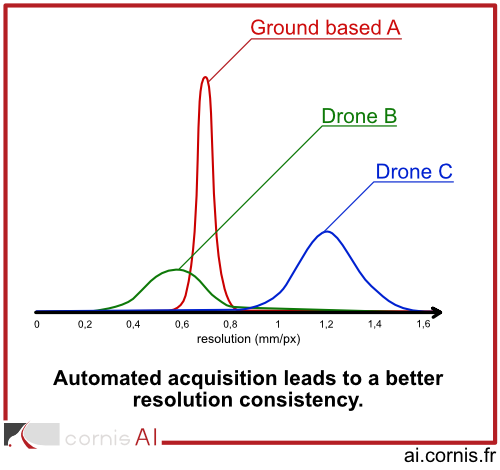

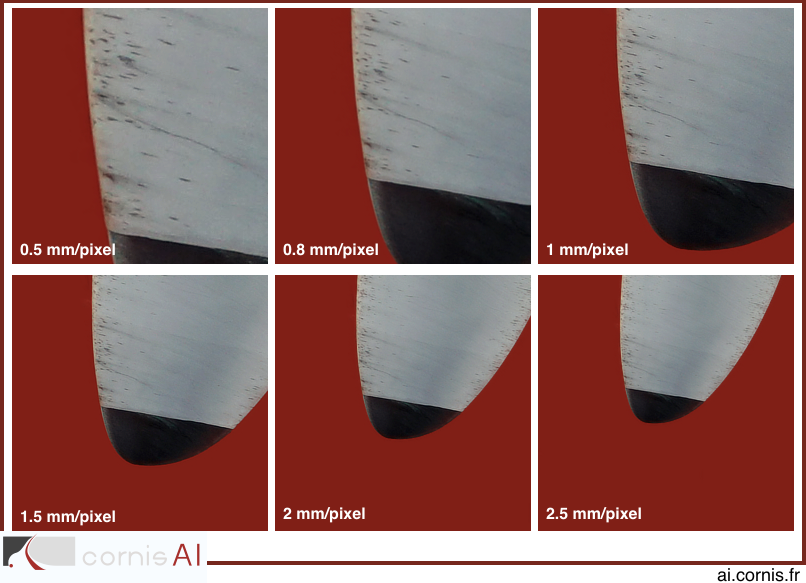

Resolution

Depending on your acquisition solution, the resoltion on images can vary a lot. At Cornis we recommend a resolution of at least 1mm per pixel. Note that the number of Mega Pixel of the camera is not enough to tell you the resolution you will obtain on the blade surface.

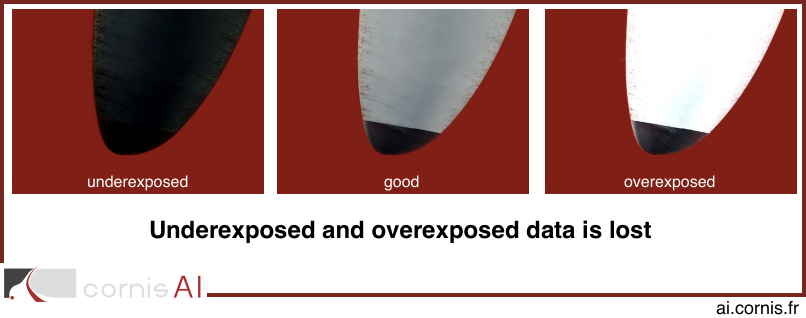

Luminosity

When you acquire pictures with a camera, you need to correctly set the camera so that every picture receives the correct amount of light. If your camera received too much light, all the details will be lost or burnt. On the contrary, if the camera received too little light, a lot of noise will be visible on the image and can cover up important details for a blade expert.

Resolution Consistency

Depending on your acquisition system, resolution can vary along the blade. Most drone inspections have lower resolution towards the hub. Automated ground-based camera tend to have a better resolution consistancy. The resolution can also vary with different inspectors and pilots.